Understanding Air Freight Containers: How the Right ULD Protects Your Cargo in the Sky

What Are Air Freight Containers and Why Do They Matter?

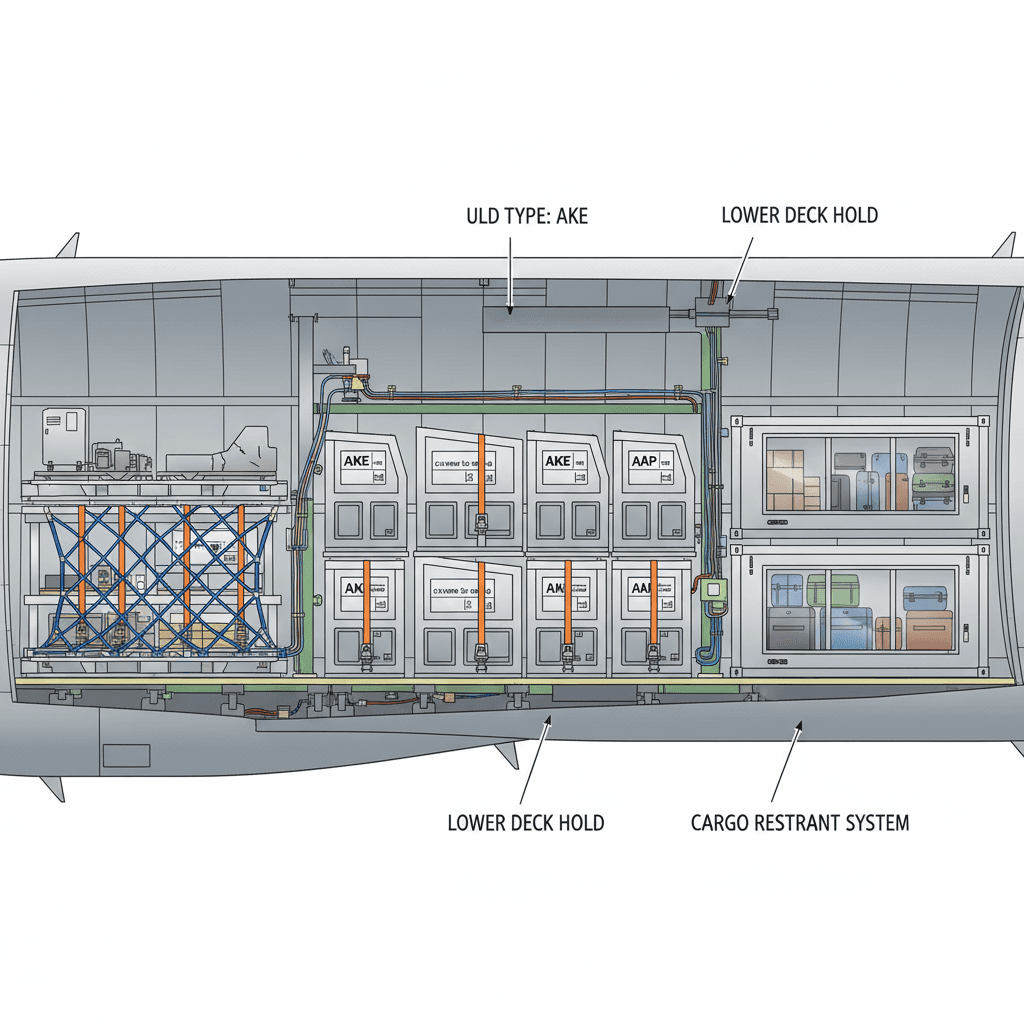

When you ship by air, your cargo doesn’t just sit loose in the aircraft hold it travels inside special equipment called airline units or unit load devices (ULDs). These are pallets or containers designed to hold loose freight securely so it can move safely through airports, loaders, and customs. By “unitizing” cargo into ULDs, airlines speed up loading and unloading, protect goods from damage, and use every inch of aircraft space more efficiently.

Two Main Types of ULDs: Pallets and Containers

Airline units generally come in two forms:

- Pallets – Flat aluminium bases with strong rims designed to lock onto cargo net lugs. Cargo is stacked on top and secured with nets or straps.

- Containers (or “cans” / pods) – Enclosed units made from aluminium or combinations of aluminium, polycarbonate, and composite sheets. Some are fully metal; others use fabric or mesh sides with solid frames. These are shaped to fit the curved fuselage of the aircraft, especially in the lower deck.

Both pallets and containers are built to airline standards so they fit perfectly and can be handled by automated equipment worldwide.

Lower Deck Containers: LD‑1, LD‑2 and More

For passenger aircraft carrying belly cargo, lower deck containers are the workhorses. Common examples include LD‑type ULDs (like LD‑1 and LD‑2), each with defined height, length, width, and cubic capacity. These containers are designed for specific aircraft such as the Boeing 747 or wide‑body jets; they slide into the curved lower hold on rollers and lock into place.

Using the correct LD container means better space utilization, less movement during flight, and faster turnaround at the airport. Airlines choose the model based on aircraft type and route, while your freight partner matches your shipment’s volume and weight to the right unit.

Air Freight Pallets: Flexible Workhorses for Large and Mixed Cargo

Air freight pallets come in several sizes such as full pallet (net or igloo) and half pallet, each with standardized dimensions and cubic capacity. Some are used for pure freighter aircraft; others are certified for both passenger and cargo aircraft. Pallets are ideal when you’re shipping:

- Heavy or bulky cargo that can be stacked and netted

- Mixed shipments going to multiple consignees

- Time‑critical freight that needs quick ground handling

The net or “igloo” covering holds everything tightly in place, reducing shifting, vibration damage, and risk during turbulence or ramp operations.

How Professionals Choose the Right Air Freight Container for You

One of the biggest advantages of working with an experienced air freight handler is that you never need to memorise container codes. Loaders and planners look at your cargo’s:

- Dimensions and weight

- Destination and route

- Aircraft type and airline requirements

- Special handling needs (fragile, temperature‑sensitive, hazardous)

Then they select the ULD model that balances safety, capacity, and cost. The right match avoids wasted space (which you still pay for), reduces damage risk, and makes sure your shipment complies with both airline and airport regulations.

Why ULD Choice Affects Cost, Speed, and Cargo Safety

Using the correct pallet or container means better consolidation, which directly influences your air freight quote. Efficient ULD planning can reduce the number of units needed, improve load balance, and help your flight depart on time. It also limits manual handling, one of the main causes of dents, tears, or crushed packages in air cargo.

For shippers, this translates into:

- More predictable pricing

- Fewer claims for damage

- Faster handling through busy hubs

- A smoother path through customs and security checkpoints

Conclusion: Let Sea Sky Cargo Handle the Right ULD for You

Air freight containers and pallets might look like simple metal boxes and flat sheets, but they quietly determine how safe, efficient, and cost‑effective your shipment will be. Choosing the right ULD means better space utilization, smoother handling on the ramp, fewer surprises in transit, and a much lower risk of damage. That decision shouldn’t sit on your shoulders, it belongs with specialists who understand aircraft types, weight limits, and airline standards inside out.

If you’re planning your next air shipment and don’t want to worry about container codes, load plans, or cubic feet, talk to Sea Sky Cargo. The team will assess your cargo, match it with the most suitable pallet or container, and manage the entire journey from booking to touchdown. Reach out today for a tailored air freight solution that keeps your goods protected in the sky and perfectly positioned when they land.