The Ultimate Guide to Ship Life Logistics: Shipping Pharmaceuticals and Medical Equipment

Introduction

You’re standing on the deck of a modern cargo vessel, sea breeze on your face, clipboard in hand, and under your feet, thousands of dollars’ worth of medicines and medical gadgets humming inside insulated containers. You’re not just shipping boxes; you’re safeguarding the lifeblood of hospitals, clinics, and patients worldwide.

This isn’t just another how-to guide. Think of it as a field manual for anyone who wants to move medical miracles across oceans, borders, and time zones with total compliance.

Why Ship Pharmaceuticals and Medical Equipment?

Picture the countless hands that touch a shipment of vaccines: scientists in pristine labs, logistics pros orchestrating routes like chess masters, and finally, medical staff at remote clinics waiting for relief. Shipping pharmaceuticals and medical equipment is more than a supply chain it’s a global safety net.

These products are highly regulated and desperately needed. Whether it’s delivering outbreak-stopping vaccines to island nations or transporting MRI machines for new hospitals in Africa, success often hinges on the invisible logistics network beneath everything. Delays, temperature swings, or regulatory mishaps can mean real lives at risk. Every detail, from timing to temperature, could spell the difference between health and harm.

Cold Chain: Not Your Average Chilled Chardonnay

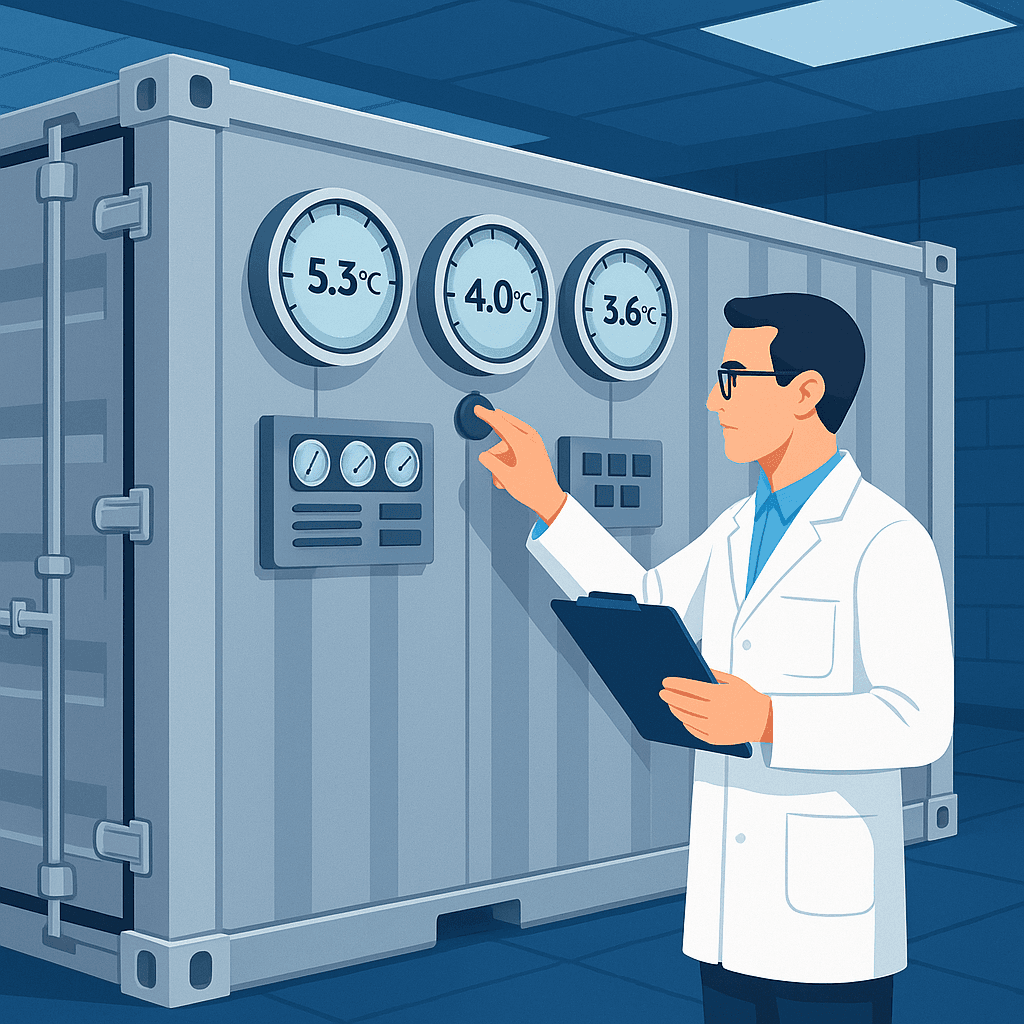

Many medicines and vaccines must be kept at specific temperatures during shipping to stay effective. This is called the cold chain.

- Some medicines can be kept at room temperature (between 15°C and 25°C).

- Many vaccines and drugs need refrigeration (between 2°C and 8°C).

- Certain products, such as biologics, require freezing temperatures, sometimes as low as -20°C or colder.

The cold chain uses special refrigerated containers and packaging to keep medicines at the right temperature. Modern shipments also include temperature sensors and GPS tracking, so you can monitor conditions in real-time and react quickly if something goes wrong.

Always remember: keeping the cold chain unbroken is crucial for the safety and effectiveness of many medicines.

Top Challenges & How to Tackle Them

Let’s face it shipping this stuff isn’t a cozy cruise. It’s an obstacle course deserving of its own Olympic medal.

- Ever-Changing Rules: Regulatory requirements evolve fast, and paperwork errors can lead to customs delays, hefty fines, or product recalls. Compliance is a moving target you need a flexible, proactive team ready to update procedures after every new memo.

- The Temperature Tango: An ill-timed blackout, traffic jam, or equipment malfunction can break the cold chain. Real-world contingency planning is a must (think back-up power, rerouting, rapid-response teams).

- Rough Rides: Choppy seas, turbulent flights, and bumpy roads can crush fragile equipment or shake medical vials into uselessness.

- Security: Medical shipments attract thieves and counterfeiters. Secure containers, tamper-evident seals, and real-time trackers help keep criminals at bay.

Pro tip: Don’t “just hope” things go smoothly. Plan, prep, and always have a Plan B—real-world shipping is anything but predictable.

Packing for Protection & Compliance

If you’ve ever received a shattered tablet or a warm “cold pack,” you know good packing is non-negotiable. For pharmaceuticals and delicate med-tech, it’s a science.

- Layered Defense: Think foam linings, insulated blankets, impact-absorbing supports, and rigid outer boxes. Some cargos need “suspension packaging” to ride out bumps like a first-class passenger.

- Tamper-Proof Everything: Good packaging isn’t just durable it’s secure. Tamper-evident seals and unique identification codes allow handlers to spot breaches immediately.

- Label Like a Pro: Every container must list its correct temperature range, contents, hazard warnings, and handling rules in a format that transcends language barriers.

- Every Link Tracked: Each handoff is logged, so if something goes wrong, you know where and when. Audits are easier. So is fixing weak links.

Choosing the Right Transport (Air, Sea, or Land?)

Land

Pros: Flexible, excellent for final-mile delivery, cost-effective for nearby shipments

Cons: Not feasible for international moves; delays from roadwork, weather, congestion

Sea

Pros: Best for massive volumes, lower price per kilo, greener (per ton-mile), customizable reefers

Cons: Weeks in transit, port delays, sensitive to humidity and temperature shifts

Air

Pros: Ultra-fast, lifesaver for emergencies, ideal for small or precious/urgent goods

Cons: Expensive, weight limits, flight delays, strict regulatory controls

Key Regulations No One Likes a Surprise Audit

Miss a single compliance requirement, and you could lose an entire shipment. Or worse.

- GDP (Good Distribution Practices): The logistics commandments—from storage to transit records that ensure quality and integrity worldwide.

- CFR in the U.S.: Federal laws dictating labeling, documentation, and handling for everything from cough syrup to chemotherapy agents.

- European Union GDP: Known for razor-sharp inspections and tough standards slip up, and your shipment may not clear customs.

- IATA for Air, IMDG for Sea: Regulations set by the world’s transport authorities, covering everything from hazmat rules to packaging, with massive consequences for violations.

The best logistics partners don’t just have regulatory binders on a shelf they internalize and update them constantly.

Best Practices for Smooth Shipping

Ready for mastery? Here’s the secret sauce:

- Plan Way Ahead: Secure permits, book slots, confirm routes, and always have alternative options for emergencies last-minute heroics rarely pay off.

- Digitize and Monitor: IoT sensors, GPS, and centralized dashboards give you real-time eyes on temperature, humidity, location, and security. Some platforms automate alerts to your team’s devices, making errors nearly impossible to ignore.

- Specialists Only: Trust medical/Pharma shipments to logistics professionals who know compliance isn’t an afterthought. Scrutinize their certifications and call references.

- Insurance is Mandatory: Products this precious need robust coverage. Tailored policies now cover loss due to spoilage, breakage, hijack, or delays.

- Relentless Self-Audits: Run regular spot-checks and simulate emergency scenarios. Your clients’ lives depend on eliminating blind spots before there’s a crisis.

Conclusion

Shipping pharmaceuticals and medical equipment isn’t just ticking boxes and meeting deadlines it’s about delivering hope, health, and innovation with every crate. From tight regulatory hoops to white-knuckle transport challenges, triumph lies in preparation, partnership, and a refusal to cut corners.